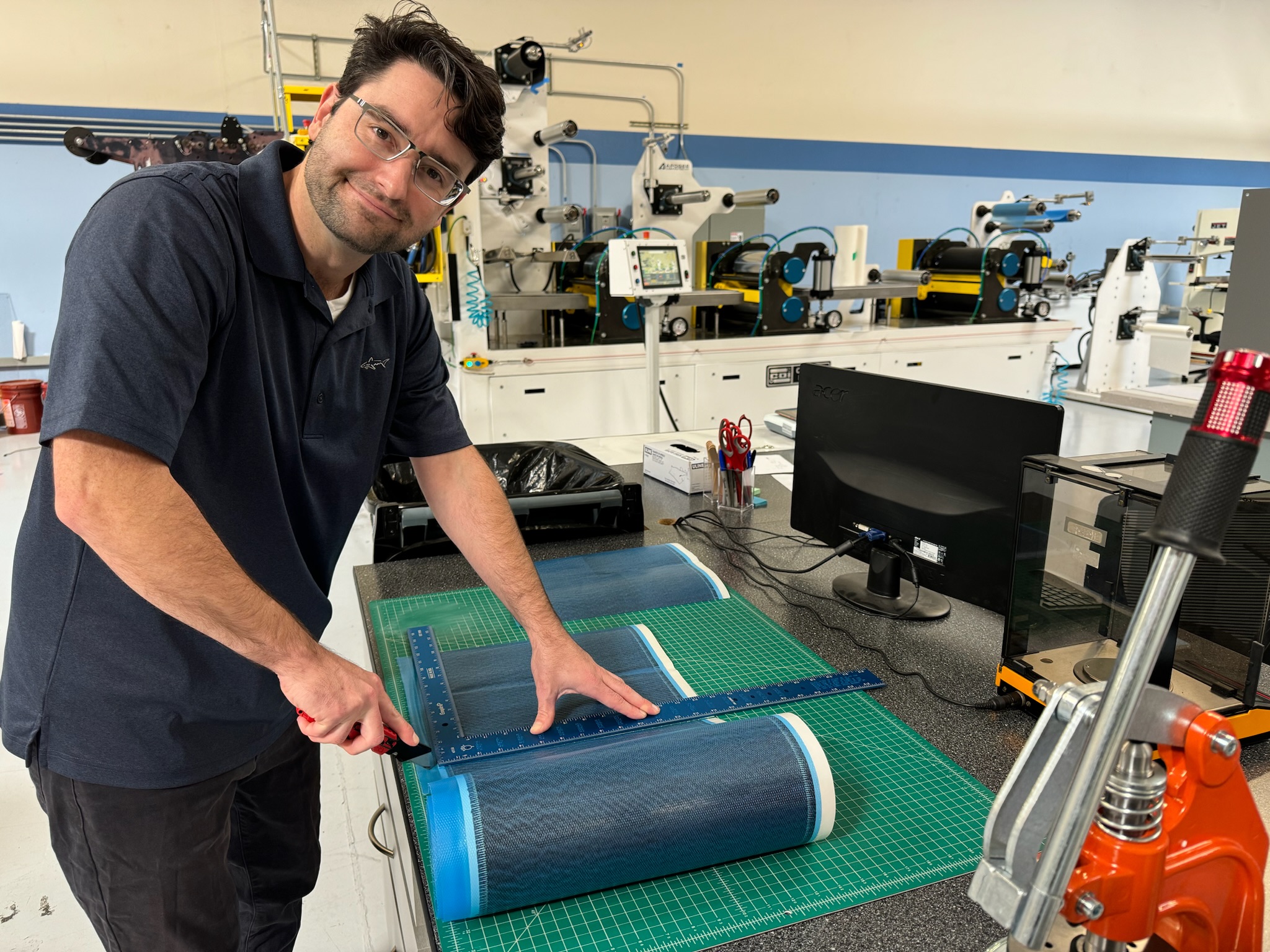

Meet Bill Edwards | Founder

We had the good fortune of connecting with Bill Edwards and we’ve shared our conversation below.

Hi Bill, we’d love to hear more about how you thought about starting your own business?

I started Apogee Composites while I was a graduate student at the University of Southern California. I was involved in research focused on the manufacturing science of carbon fiber composite structures where I helped develop a method for producing composite structures that was faster, cheaper, and more reliable that current industry practices. When we saw the potential impact of the technology, we approached several existing composite materials manufacturing companies to convince them to adopt our approach, but most of the companies we talked to did not think the technology was mature enough to deploy.

After hitting this roadblock, Apogee was founded to take matters into our own hands. We began pitching our technology and business plan to venture capital groups, private equity, and angel investors to raise the funds necessary for a pilot manufacturing facility. Most potential investors indicated that they recognized the value proposition of our technology, but that we that they wouldn’t be ready to invest until Apogee Composites was more mature. One private equity group, however, decided to give Apogee a chance and put up the money necessary to lease a facility, purchase manufacturing equipment, and start producing our proprietary format of carbon fiber material. We’ve been operating out of our facility in south LA since we had manufacturing equipment installed in 2024.

What should our readers know about your business?

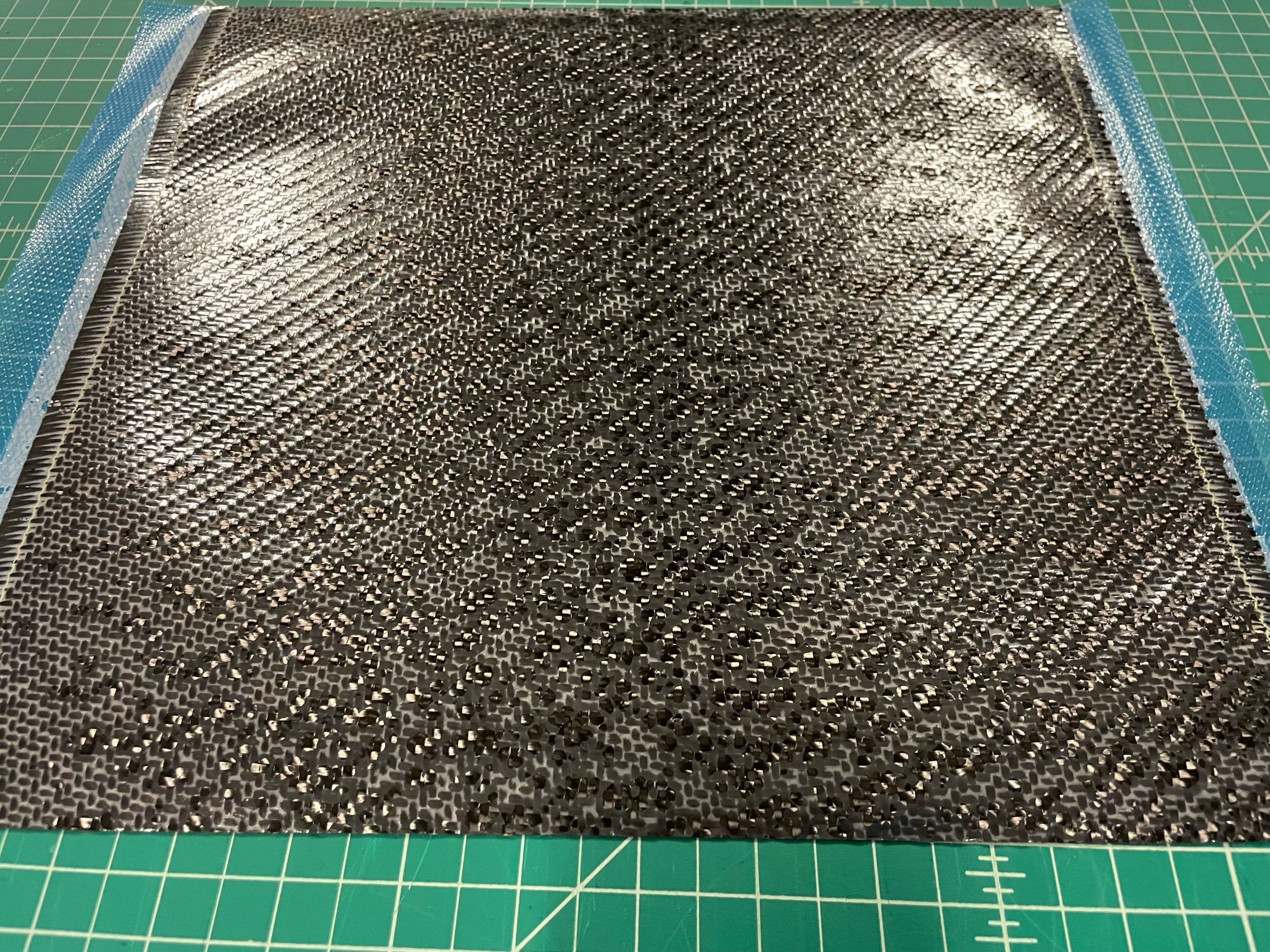

Apogee Composites exists to help democratize the production of carbon fiber composites. Today, reliable production of composite structures requires expensive manufacturing equipment, lots of electricity, and years of technical expertise. We are working to significantly reduce the equipment, time, energy, and expertise required to produce high-quality composite structures. The unique reliability of our carbon fiber material means that our customers do not have to purchase or operate expensive manufacturing equipment, and that even a hobbiest can produce aerospace-quality structures in their garage at home. Widespread adoption of our product and process would reduce the environmental impact associated with composites manufacturing by significantly reducing the electricity required for manufacturing and by minimizing the number of parts rejected and sent to the landfill. Our technology may also increase the number of applications where integration of carbon fiber composites makes economic sense, providing a variety of opportunities to customers and end users for improved fuel efficiency, better performance, and reduced environmental impacts.

Getting Apogee off the ground has not been easy. Probably the most important factor behind our success is persistence. Apogee has faced many challenges: developing an effective technology, finding funding to open a manufacturing facility, modifying manufacturing equipment, designing and reliably producing high-quality product, and establishing a sales pipeline. Any one of these problems could have been intimidating enough to justify giving up, but our commitment to working through these problems and finding effective solutions has meant that we are still here serving the community. Growing up, my dad always told me “Bill, if you like problems, you’re going to like life.” Turns out I really like problems, so I’ve loved finding solutions to all of Apogee’s obstacles on the road growth and success.

If you had a friend visiting you, what are some of the local spots you’d want to take them around to?

I have a couple go-to activities that I like to do with friends when they visit LA. First, I usually try to sweet talk my buddy into taking us out on his sailboat boat in Marina del Rey (bribing him with a case of beer or some fancy cheese/charcuterie often helps). On the way to the boat, we’ll pick up breakfast tacos from Homestate. They make excellent tacos and their tortillas are fantastic. After meeting on the dock, we’ll cruise around Santa Monica Bay, checking out the Venice Beach and Santa Monica piers and giving everyone a chance to drive the boat or trim sails. After sailing, we’ll go to Wurstküche in Venice for some grilled sausages and Belgian fries, and we’ll probably end the night with some drinks at Bigfoot Lodge West.

Other activities I often pitch to visiting friends include hiking or mountain biking in the Santa Monica Mountains, wingfoiling at Cabrillo Beach in Long Beach, and taking the dog for a walk in Griffith Park. Highland Park Bowl is also a great place to check out. They are LA’s oldest bowling alley, and they have a very fun, retro, steam punk vibe. It’s a great place to go bowling and have something to eat or drink. Speaking of eating, if visitors are foodies looking for nice sit down dining experiences, I always suggest checking out Bestia, Osteria Mozza, and Cento Pasta Bar. I also always insist on sharing LA’s best Mexican food with visitors: Bee Taqueria makes fantastic, unique street tacos, and my favorite street vendor serves up LA’s best pastor burritos and horchata in the Ralphs parking lot on the south east corner of La Brea and Obama.

The Shoutout series is all about recognizing that our success and where we are in life is at least somewhat thanks to the efforts, support, mentorship, love and encouragement of others. So is there someone that you want to dedicate your shoutout to?

Oh wow, so many people deserve credit and recognition for where Apogee is today. There are too many people to call them all out, but Mike Richarson, Prof. Steve Nutt, and my parents all deserve a ton of credit for supporting Apogee and getting me to where I am today. My business partner and Apogee’s CFO/COO Mike Richardson has been an irreplaceable leader in managing fundraising and financing for Apogee. He also hasn’t been afraid to get his hands dirty, going elbows deep in epoxy to help to develop products and refine manufacturing operations. Without Mike, Apogee wouldn’t have a facility, manufacturing equipment, or the variety of products that we offer today. Prof. Steven Nutt has also been a critical part of the Apogee team. Prof. Nutt was my doctoral advisor at USC where he oversaw the birth and development of the manufacturing technology that Apogee has commercialized. Without Prof. Nutt’s support, the technology behind Apogee would never have been developed, and the Apogee would have no basis for existing. Finally, my parents Tom and Ruth deserve a lot of credit for their love, support, and encouragement. They modeled kindness and generosity; they challenged me to work hard; they demonstrated that everyone is worthy of respect and has something to offer; they cultivated critical, independent thinking; they enabled backcountry adventures that taught me self-reliance and teamwork in equal measure. All of these lessons have been fundamental in founding and operating Apogee.

Website: https://www.ApogeeComposites.com

Linkedin: https://www.linkedin.com/company/apogee-composites-llc/

Image Credits

Sara Price; Natalie Richardson